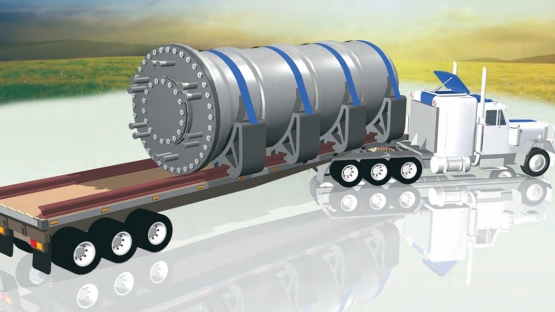

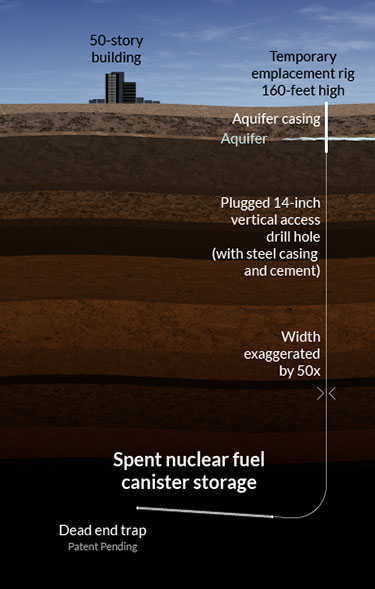

Holtec International, a Florida-based company, aims to rail thousands of canisters of spent nuclear fuel to Lea County, New Mexico, United States, and store the containers below ground. The site has a 40-year license and could ultimately hold around 170,000 metric tons of used radioactive fuel—about twice as much as the U.S. currently holds. It would be the largest such facility in the world, and Holtec says it would further the development of U.S. nuclear energy. [This plan is opposed by Fasken Oil and Ranch] a company that claims that a nuclear incident in the Permian basin, which cranks out more oil than Iraq and Libya combined, would have devastating consequences for U.S. energy and the local economy. “I’m not antinuclear,” Fasken Assistant General Manager Tommy Taylor, said. “We just don’t feel like siting all the nuclear waste in the middle of our biggest oil and gas resource is a good idea.”

Fasken said the nuclear-waste storage sites threaten its operations in the Permian. According to the court filing of Fasken:

“The proposed site sits on top of and adjacent to oil and gas minerals to be developed

by means of fracture stimulation techniques. Currently, drilling techniques used to

extract minerals in the Permian Basin involve drilling horizontally into deep

underground formations up to two miles beneath the earth’s surface. High pressure

fluids are pumped into the wells, in some cases exceeding twelve thousand pounds

per square inch. This pressure is power enough to fracture the surrounding rock

thus releasing the oil and gas. The pressure creates fissures and cracks

beneath the surface. And, at this time, there are oil and gas operators testing a new

technique of simultaneously drilling and fracturing up to 49 horizontal wellbores in

a single section of land. Either the traditional or new and unproven drilling

technique, involving more than 20,000,000 bbls of water and sand, could

conceivably be utilized to inject into and withdraw from the rock formation beneath

and surrounding the Holtec site. Hydraulic fracturing beneath and around Holtec

should give the NRC pause and is sufficient reason not to proceed.” (HOLTEC INTERNATIONAL’S ANSWER OPPOSING FASKEN’S, pdf)

The yearslong fight has entangled large oil companies, the country’s top nuclear regulator, the states of Texas and New Mexico, as well as local communities that want to host the nuclear waste.

Supporters of the nuclear-waste projects say they could help break a decades-old nuclear waste logjam that has led to radioactive refuse piling up at reactors. President Biden and billionaire investors are endorsing new nuclear projects to reduce greenhouse-gas emissions, but the U.S. has yet to figure out where to permanently unload some of the most hazardous material in the world. The Permian is home to two sites that handle some types of nuclear waste and to the only commercial uranium-enrichment facility in the country. Holtec’s storage would be temporary, and some nuclear experts say interim facilities can be a stopgap until the federal government builds a permanent, deep geologic repository. A plan to house nuclear waste at Nevada’s Yucca Mountain fizzled under former President Barack Obama, and the search for an alternative site has stalled.

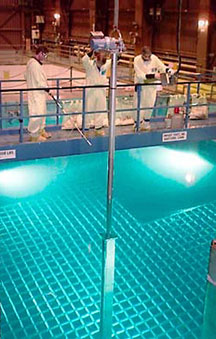

As a result, the US federal government is paying utilities billions of dollars to keep used fuel rods in steel-lined concrete pools and dry casks at dozens of sites. Consolidating used nuclear fuel at one or two facilities would lessen that financial

Fasken has notched court victories. Last year, the U.S. Fifth Circuit Court of Appeals in New Orleans found that federal law didn’t authorize the Nuclear Regulatory Commission to license a private, away-from-reactor storage facility for spent nuclear fuel. It vacated the federal license for another storage project proposed by Interim Storage Partners, a joint-venture between Orano USA and Waste Control Specialists. The Nuclear Regulatory Commission has asked the court to reconsider.

The Holtec project faces other hurdles. New Mexico last year passed legislation all but banning storage of high-level nuclear waste. Texas lawmakers have also opposed interim storage facilities. The Holtec spokesman said the company was evaluating the legislation’s impact on the project. Fasken expects the fight over interim storage will eventually reach the Supreme Court.

Excerpts from Benoit Morenne, The War over Burying Nuclear Waste in America’s Busiest Oil Field, WSJ, Feb. 19, 2024